Choosing the Right Auger Speed for Drilling Various Soils

When you’re working with drilling equipment, the fine line between a successful project and a costly mistake often comes down to understanding how soil conditions affect your operations and equipment. Choosing the right auger speed for drilling various soils isn’t about turning up the power and hoping for the best. It requires a methodical approach that considers soil composition, moisture content, and the specific characteristics of your drilling equipment.

Different soil conditions demand different approaches, and getting this balance wrong can lead to equipment damage, poor hole quality, or project delays. Learn how to optimize your drilling performance, reduce wear on your equipment, and deliver consistent results across varying ground conditions.

Soil Classifications and Their Impact

Soil classification systems provide the framework for making informed decisions about the appropriate auger speed settings for your project. The three primary categories—clay, sand, and loam—each present distinct characteristics that will directly influence your drilling approach.

Clay

Clay soils exhibit high cohesion and can become extremely sticky when wet. These conditions typically require slower auger speeds to prevent the material from balling up on the flights and creating blockages. The dense nature of clay means that higher torque at lower speeds often proves more effective than attempting to power through at maximum RPM.

Sand

Sandy soils behave differently, offering less resistance but presenting their own challenges. The loose, granular structure allows for faster drilling speeds, but the material tends to fall back into the hole if consistent progress is not maintained. Finding the sweet spot between speed and control becomes crucial for this particular soil type.

Loam

Loamy soils represent a middle ground, combining the elements of both clay and sand. These mixed conditions often provide the most forgiving drilling environment, but they still require careful attention to speed settings based on which soil component dominates the mixture.

Speed Considerations for Clay-Heavy Soils

Working with clay-heavy soils requires patience and precision in selecting your speed. These dense, cohesive materials respond best to lower RPM settings combined with steady downward pressure. Start with speeds in the 20–30 RPM range to allow the auger flights to cut through the material cleanly without creating excessive friction that leads to balling.

Wet clay becomes incredibly sticky and can completely clog your auger if you attempt to drill too quickly. During these conditions, reducing your speed even further, sometimes to as low as 15 RPM, helps maintain clean cutting action and prevents material buildup on the flights.

Dry clay presents the opposite challenge, becoming extremely hard and requiring more aggressive cutting action. While you might need to increase speed slightly for dry conditions, the emphasis should remain on torque rather than RPM.

Optimal Speed for Sandy and Granular Soils

Sandy soils allow for much higher drilling speeds due to their loose, non-cohesive nature. Speeds in the 40–60 RPM range often work well for clean sand, enabling rapid penetration while maintaining good hole stability. However, the main challenge with sandy materials involves preventing cave-ins and ensuring efficient material removal from the hole.

Fine sand tends to pack more tightly and may require slightly reduced speeds to maintain control, while coarse sand and gravel mixtures can often handle the higher end of the speed range. Pay attention to how the material behaves as it comes up the auger flights; smooth, consistent flow indicates you’ve found the right speed.

Speed for Mixed Soil Conditions

Real-world drilling projects rarely involve uniform soil conditions throughout the entire depth. Mixed soils require constant attention and speed adjustments as you encounter different layers. Having the ability to recognize changing conditions and adapt your approach separates experienced operators from beginners.

When transitioning between soil types within a single hole, gradual speed adjustments are more effective than dramatic changes. If you’re moving from sandy topsoil into a clay layer, begin reducing your speed as soon as you notice the change in material.

Environmental Factors Affecting Speed Selection

Weather conditions can impact soil behavior and optimal auger speed settings. Recent rainfall can transform easily drilled sandy soil into challenging, muddy conditions that demand completely different speed approaches. Conversely, extended dry periods can turn normally workable clay into rock-hard material that requires patient, low-speed drilling.

Temperature also affects soil consistency, particularly in areas with high clay content. Cold weather can make clay more brittle and easier to drill at moderate speeds, while hot conditions may cause clay to become more plastic and sticky. Adjusting your speed in response to these temperature-related changes helps maintain consistent drilling performance.

Equipment Considerations and Speed Limitations

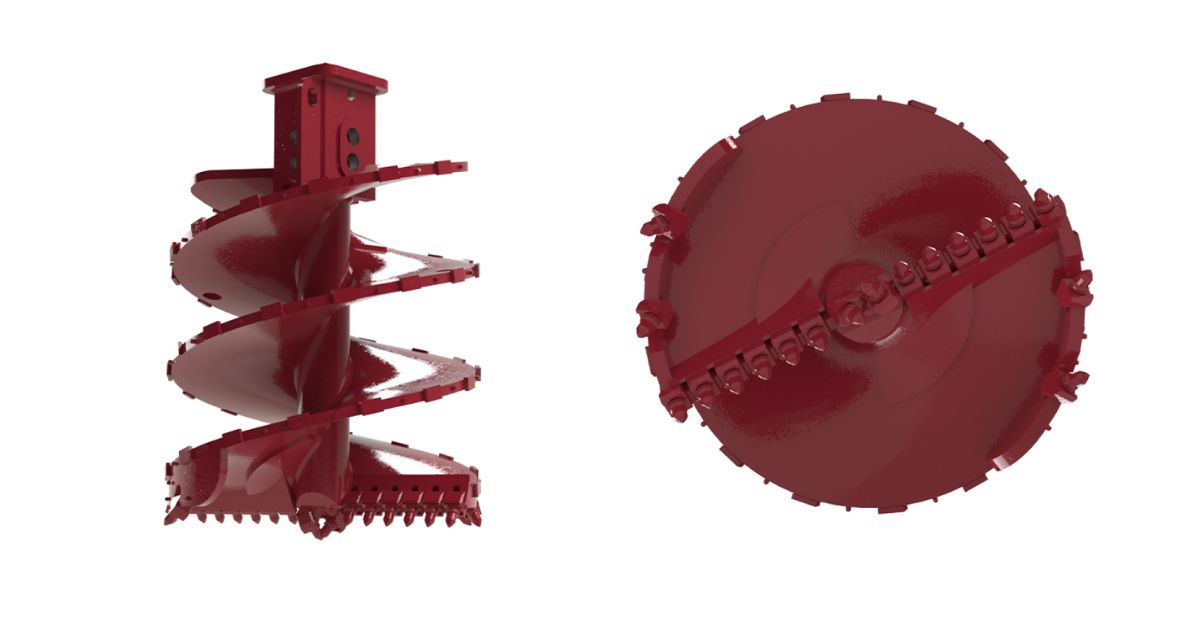

Your specific auger equipment imposes certain limitations that must be considered in conjunction with soil conditions. Different auger designs, such as continuous flight, double flight, or specialized cutting heads, each have optimal operating speed ranges that shouldn’t be exceeded, regardless of soil type.

The power output of your drilling equipment directly affects your ability to maintain consistent speeds under varying load conditions. Lower-powered units may bog down in heavy clay even at relatively slow speeds, while high-torque equipment can maintain steady progress through challenging situations. Understanding your equipment’s capabilities helps you set realistic speed expectations.

At Jeffrey Machine, we provide high-quality, durable, and reliable foundation drilling augers designed to handle any project with ease and efficiency. Built to last, these augers deliver exceptional performance, making them the go-to choice for professionals seeking dependable equipment for their foundation drilling needs.

Maximum Efficiency Through Proper Speed Management

Effective speed management goes beyond simply selecting the right RPM for each soil type. It involves developing a systematic approach that considers project requirements, equipment capabilities, and changing ground conditions throughout the drilling process.

Monitoring your auger’s performance provides valuable feedback for speed optimization. Smooth, consistent material flow up the flights indicates optimal speed selection, while erratic behavior or material buildup suggests the need for adjustment. Learning to read these signs helps you maintain peak efficiency throughout your drilling operations.

The quality of your finished holes directly reflects the accuracy of your speed selection. Properly drilled holes maintain their intended diameter, exhibit smooth walls, and resist caving or sloughing. When you consistently achieve these results, you know you’ve mastered the relationship between soil conditions and auger speed.

Achieving Drilling Success Through Informed Speed Selection

Mastering the art and science of choosing the right auger speed for drilling various soils requires combining technical knowledge with practical experience. Success in drilling operations comes from treating each project as a learning opportunity.

Document what works well in different soil conditions, note how weather affects your speed requirements, and build a personal reference guide that reflects your equipment’s capabilities and limitations. This systematic approach transforms challenging drilling conditions into manageable, profitable projects.