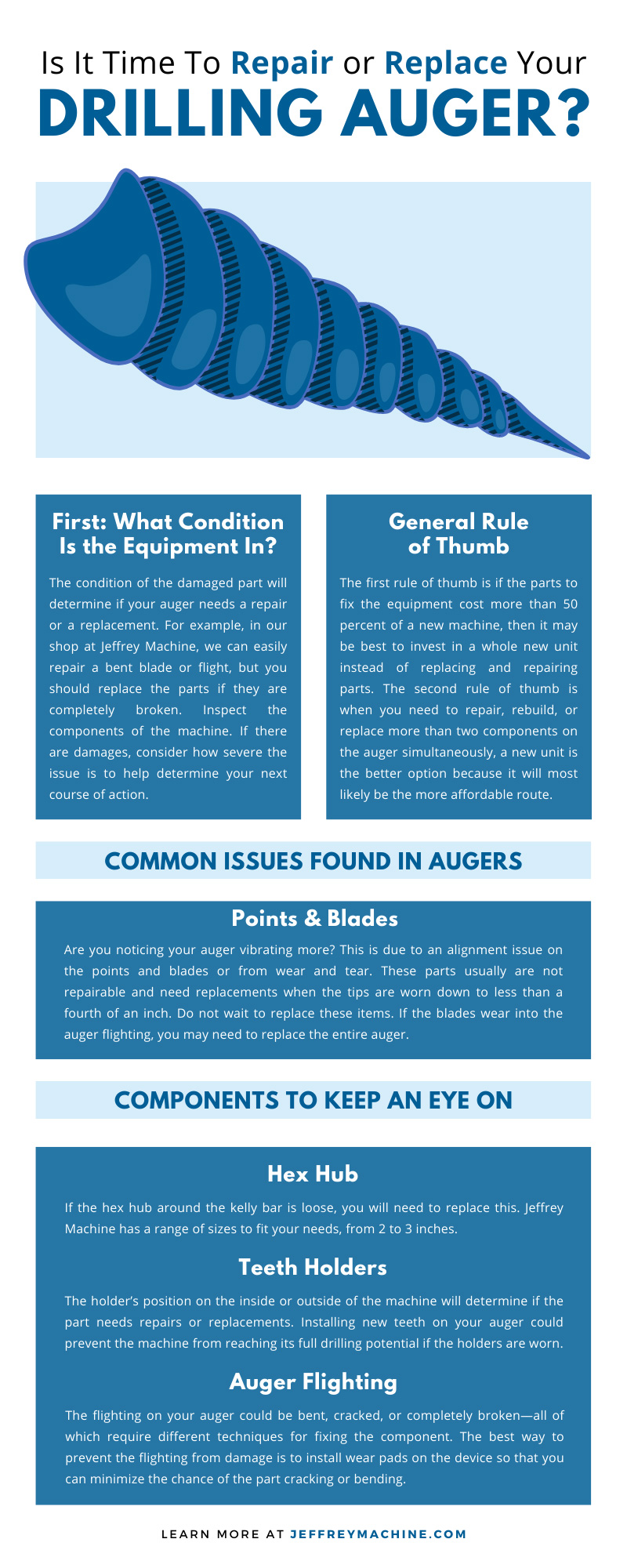

Is It Time To Repair or Replace Your Drilling Auger?

Before your drilling auger reaches a point where you must repair it, understand when it’s time to replace its components. Purchasing a whole new tool could be expensive and not always feasible. Repairing parts here and there is the most cost-effective option and allows you to get your auger’s full use before needing to purchase a new one due to extensive damages.

Below, you can find tips for configuring the best options for your business and its machines. Furthermore, you will be able to identify common issues with the equipment and what parts experience damage.

First: What Condition Is the Equipment In?

The condition of the damaged part will determine if your auger needs a repair or a replacement. For example, in our shop at Jeffrey Machine, we can easily repair a bent blade or flight, but you should replace the parts if they are completely broken. Inspect the components of the machine. If there are damages, consider how severe the issue is to help determine your next course of action.

If you are unsure whether you should repair a part, you can contact us at Jeffrey Machine and speak with our knowledgeable experts. Our team has the capacity to repair, rebuild, or replace auger tooling parts on various machines. Do not wait until the issue is unfixable, because it can cost you more money to repair or replace the part—send it to our staff as soon as possible to prevent further issues.

General Rule of Thumb

The first rule of thumb is if the parts to fix the equipment cost more than 50 percent of a new machine, then it may be best to invest in a whole new unit instead of replacing and repairing parts. The second rule of thumb is when you need to repair, rebuild, or replace more than two components on the auger simultaneously, a new unit is the better option because it will most likely be the more affordable route. Remember these rules when determining if it’s time to repair or replace your drilling auger.

Common Issues Found in Augers

When you use an auger for drilling foundations, you should know the common issues that could arise with the machine. Knowing what could go wrong on the job allows you to make better decisions when repairing or replacing parts.

Points & Blades

Are you noticing your auger vibrating more? This is due to an alignment issue on the points and blades or from wear and tear. These parts usually are not repairable and need replacements when the tips are worn down to less than a fourth of an inch. Do not wait to replace these items. If the blades wear into the auger flighting, you may need to replace the entire auger. Worn-down points and blades can no longer function properly and could cause issues on the construction site, so you must replace them as soon as possible.

Components To Keep an Eye On

There are a few key components you should keep an eye on when performing job functions at a construction site. To prevent these parts from further damage, you must keep an eye on the more fragile components. Aside from common issues with an auger, the following parts are the most likely to receive damage, and you must repair or replace them before the machine is beyond repair.

Hex Hub

If the hex hub around the kelly bar is loose, you will need to replace this. Jeffrey Machine has a range of sizes to fit your needs, from 2 to 3 inches. If this component becomes loose throughout the job, consider replacing it.

Teeth Holders

The holder’s position on the inside or outside of the machine will determine if the part needs repairs or replacements. Installing new teeth on your auger could prevent the machine from reaching its full drilling potential if the holders are worn. The inside holders will need replacements from time to time, but you can repair an outside holder by welding a hard-facing wire on the hardware.

Auger Flighting

The flighting on your auger could be bent, cracked, or completely broken—all of which require different techniques for fixing the component. The best way to prevent the flighting from damage is to install wear pads on the device so that you can minimize the chance of the part cracking or bending. As long as the flighting isn’t completely broken in half, you can repair the part.

Above all else, inspect your equipment regularly and perform maintenance on the machine when appropriate to keep up with damages. Allow Jeffrey Machine to help in repairing and replacing your auger parts. We work on all sizes and types of augers. We can ship the tooling back to you once we complete the work. Keep an eye on your equipment to prevent damage to the machine and injuries to the workers.