How Core Drilling Is Used in Construction

No matter your construction project, you will likely need to use core drilling at least once. Core drilling is a popular method for creating boreholes for various uses. Keep reading to know what this method entails, how core drilling is used in construction, why and how you should use it, and much more.

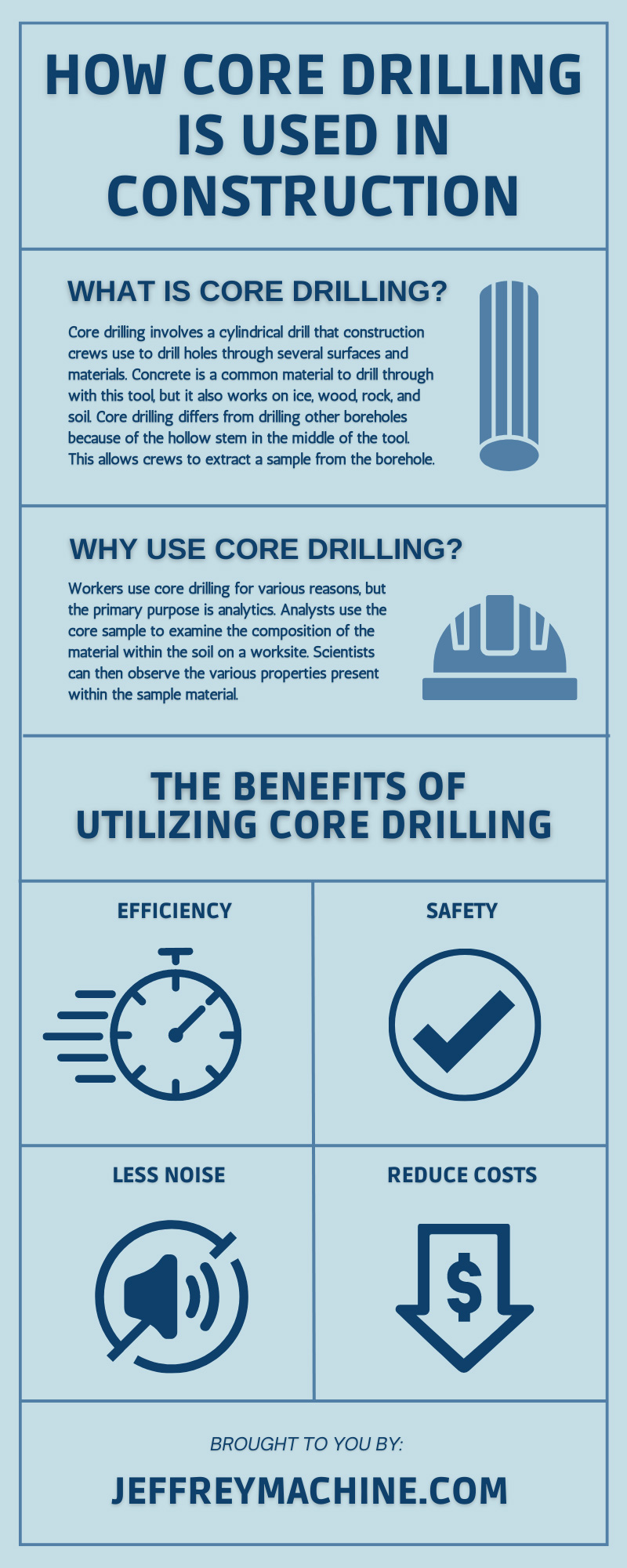

What Is Core Drilling?

Core drilling involves a cylindrical drill that construction crews use to drill holes through several surfaces and materials. Concrete is a common material to drill through with this tool, but it also works on ice, wood, rock, and soil. Core drilling differs from drilling other boreholes because of the hollow stem in the middle of the tool. This allows crews to extract a sample from the borehole.

How Does Core Drilling Work?

Every core drilling barrel has teeth on the underside that help drill through surfaces. The teeth are typically coated in industrial diamond or carbide to help enforce the grinding of the tool through hard materials to create a borehole. Because of how dense and hard this material is, you will need diamond teeth on your core barrel to drill through concrete.

The drill operator will mount the tool or core barrel onto a drilling machine shaft to apply torque and pressure for drilling. You must also secure and anchor the machine onto the structure you’re drilling through for better stability.

However, before you proceed with drilling, you must ensure it’s safe. Many construction crews enlist the help of ground-penetrating radar (GPR) concrete scanning to evaluate the structure and surrounding area of the work site to ensure it’s safe to proceed with drilling. This is also a non-destructive way to determine the quality of your drilling surface.

Once you’re clear and safe to drill, you can begin the process. The hollow middle of the core barrel will accumulate material called a core sample. You can use this sample after completing the drilling process to assess the strength and stability of the structure.

Why Use Core Drilling?

Workers use core drilling for various reasons, but the primary purpose is analytics. Analysts use the core sample to examine the composition of the material within the soil on a worksite. Scientists can then observe the various properties present within the sample material. This helps to analyze material strength, quality, present deterioration, capacity, and how much weight the material can hold.

You might also use the efficiency and accuracy of core drilling to help the success of various other construction projects. In the next section, we give examples of the projects for which you might use the core barrel.

What Construction Projects Use This?

Not only is core drilling suitable for retrieving material samples, but it’s also efficient for many construction projects. For example, core drilling is used in the construction or remodeling of buildings because the core barrel can cut holes through concrete structures to install new sprinkler systems, pipework, phone lines, and more.

However, that is not all. You may find crews using this drilling method to create culverts and maintenance holes, build parking garages, install airport runway lighting, aid in electrical services, and nuclear decommissioning. Core drilling has multiple uses, so it’s essential to construction projects.

The Benefits of Utilizing Core Drilling

While there are plenty of other drilling methods you could use in construction projects, core drilling has many benefits. Now that you understand how to use this method in projects, take advantage of this foundation tool’s benefits.

It’s Efficient

First, the drill bit, or core barrel, is efficient with drilling holes. The work is precise, accurate, and produces cleaner boreholes.

Smaller Messes

Using other drilling methods could kick up a lot of dust and debris during the process. Core drilling reduces dust levels, making a smaller mess. This is also great for protecting operators from respiratory distress due to the high levels of dust and debris in the air.

Optimized Safety

Throughout the process of drilling through the concrete of a structure, core drilling creates less risk to optimize safety on a work site. You can also maintain the integrity of the structure you’re drilling.

Less Noise and Disruption

Noise is inevitable on a construction site, but core drilling can keep noise levels to a minimum. For example, a hammer drill creates excess vibrations and noise, disrupting the surrounding homes and businesses. If your work site is near hospitals or schools, consider core drilling because it produces much less noise.

Different Types of Core Drilling

You can use the core drilling method in both wet and dry drilling and inverted drilling. Wet core drilling uses water as a lubricant to help loosen the surface of the borehole, allowing the drill to move faster and produce a cleaner, more stable hole. You might use this for installing pipe into masonry.

Dry drilling uses the core barrel bit as intended without lubrication from water. However, it puts more stress on carbide teeth when you don't use lubrication. Usually, wet core drilling is the method of choice, but you would use dry drilling for electrical work because water and electricity do not mix well.

As you can see, core drilling has many uses in the construction industry. It’s also an effective way to drill through tougher materials such as rock or concrete. Jeffrey Machine has various core drilling foundation tools to choose from; browse our website to find the appropriate tools for your construction project. If you have any questions regarding the tools and equipment, do not hesitate to reach out. Our professional staff is happy to help!