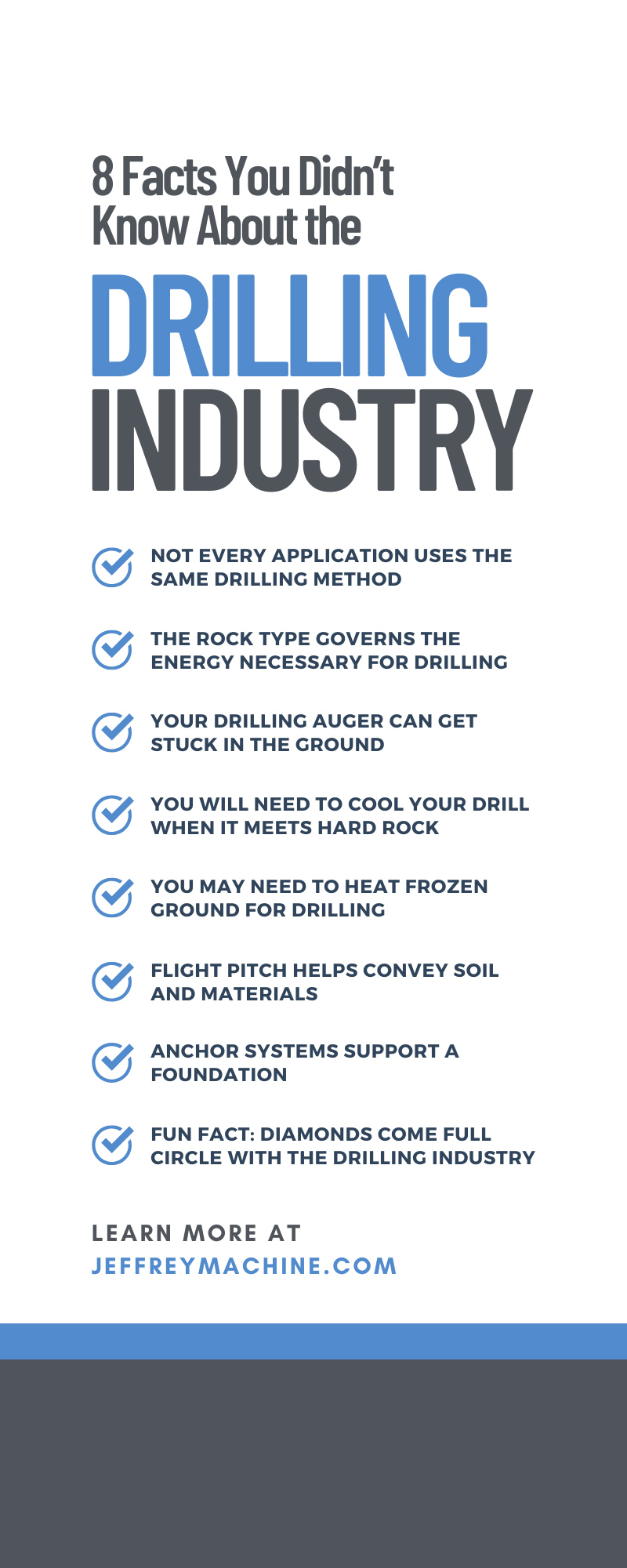

8 Facts You Didn’t Know About the Drilling Industry

We use methods in the drilling industry for several types of applications. We use core drilling for cutting through concrete, foundation drilling for stabilizing structures, oil drilling for accessing resources in the earth, and so much more. Learn more about this equipment and how we use it by reading some facts you didn’t know about the drilling industry.

Not Every Application Uses the Same Drilling Method

There are several types of drilling methods within the industry. This includes core drilling, kelly drilling, down-the-hole drilling, grab drilling, and more. Depending on your application, you would use a different drilling approach to complete a task successfully. For example, when you need to reach a greater depth in the earth using large drilling diameters, you would use kelly drilling.

Choosing the incorrect drilling method could result in mistakes in the project, ruined equipment, or injury. Step back from your application and consider which method will provide the best results.

The Rock Type Governs the Energy Necessary for Drilling

Just like not every application requires the same drilling methods, the same goes for the type of tool or auger you use. For instance, there are rock and dirt augers—you can guess which is used for which type of soil.

Obviously, rock augers work great for creating holes in ground that has hard rock embedded into the soil. Using a dirt auger for this will not provide enough energy or force to drill through the rock.

Because of this, you must know what type of soil you’re working with before choosing your type of auger tool. Once you understand what the soil entails, you can make the best decision for what equipment to use. Ignoring this will prematurely damage your gear because you’re forcing it to perform a job it was not made for.

Your Drilling Auger Can Get Stuck in the Ground

The equipment we use in construction cannot be perfect 100 percent of the time. While we can plan for mishaps and mistakes, we cannot always avoid them.

When you’re drilling with an auger, you might notice that the tool gets stuck in the ground from time to time. This isn’t necessarily something you could have prevented, but you must be careful when you’re removing it from the soil. Forcing your foundation drilling auger from the earth could damage the equipment or cause injuries to you and anyone else in the vicinity.

Some techniques to help remove a stuck auger include Reversing the tool, dampening the soil, or removing dirt from the surface of the borehole. Using those techniques helps loosen the auger so you can safely pull it from the hole.

You Will Need To Cool Your Drill When It Meets Hard Rock

With repeat friction against two hard surfaces, the drill area increases in temperature. This happens when you’re drilling through hard rock and could cause your equipment issues if you do not control the heat.

To accommodate this constraint in drilling, you must cool and lubricate your auger or drill during the application. You can pour water down the borehole as you’re drilling to help maintain the temperature of the drill.

You May Need To Heat Frozen Ground for Drilling

Winter and cold weather can hinder drilling depending on your location and region. When the ground is frozen solid, it’s very difficult to break through the earth and drill a borehole. Therefore, you may need to use various methods for heating the ground so it’s easier to drill through it.

You can use an attachment on your equipment called a ripper that helps break up the top layer of frozen soil. Some companies might even use a hydrovac to spray warm water over the surface, helping warm the soil. Either way, ensuring the ground isn’t too frozen is essential, or it could potentially break or damage your drilling equipment.

Flight Pitch Helps Convey Soil and Materials

If you’re having trouble conveying soil to the surface of your borehole, it could be because of your auger’s flight pitch. Flight pitch is the space between each spiral of the flighting. When there is too much space between the flight pitch, the ground material can slide back into the borehole, which can be very frustrating.

So if you’re having issues with displacing and conveying the soil up to the surface of the borehole, you may need to change the flighting on your auger. How dense the soil is can help determine the correct flight pitch. Mainly, use a flat pitch for loose soils and a steep pitch for denser soils.

Anchor Systems Support a Foundation

Not every foundation you pour will be capable of holding its own weight. However, you can install anchors to help distribute the weight for a more stable structure. For instance, helical pier anchors penetrate the soil to transfer the weight of the structure’s load to load-bearing soil. In other words, if your foundation is unstable in weak soil, the anchor can reach further into the ground to utilize more stable soil. Overall, anchor systems are crucial to the drilling industry because they provide support.

Fun Fact: Diamonds Come Full Circle With the Drilling Industry

Did you know that the mining industry is technically using diamonds to drill for more diamonds? This sounds confusing, so let’s break it down.

Drilling is central to the mining industry because it allows us to explore new minerals beneath the earth’s surface. A lot of the time, drilling equipment utilizes diamonds embedded into the drill to help cut through hard materials. So when you’re using a drill with embedded diamonds to mine for more diamonds, everything comes full circle. It’s a fun fact you didn’t know about the drilling industry!

From oil drilling to foundation drilling, many industries and construction applications utilize drilling equipment to ensure successful jobs. Continuing your education in your industry is necessary to learn new things and better your processes. What other facts about drilling and augers did you learn that we should know about?